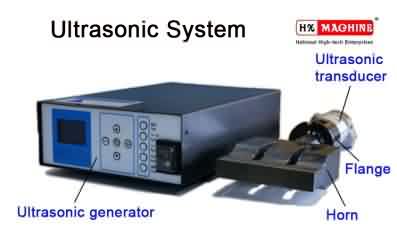

Ultrasonic is one kind of mechanical wave, which is composed of a power supply system and an ultrasonic vibration system . It is a reciprocating mechanical energy of high frequency, high power, which is out-put by the driving power. And the matched parameters as well as core component is the key point of ultrasonic technology.

Digital automatic frequency recovery ultrasonic generator→ Transducer (Produce ultrasound wave) →Ultrasonic Horn (Enlarge ultrasonic)→Mold Head (Transmit ultrasound)

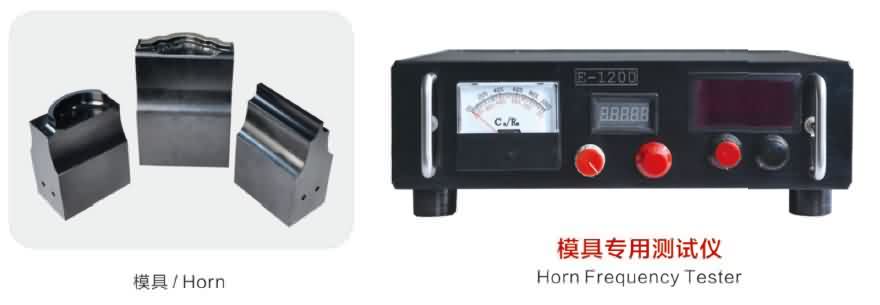

And pros and cons of mold making is an important part of the ultrasonic, we introduce advanced blocking analyzer, mold spectrum analyzer , through precise testing for mold's frequency and analysis of mold's wave by these equipment.thus can help machine with more stable and effective output power of ultrasonic.and reduce the chronic damage because of incompatible frequency with machine, what's more, prolong life for machine and mold.

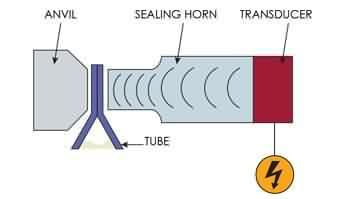

For Plastic tube sealing patterns, have different sealing type,it is suggested depending on different customer requirements.

With Ultrasonic sealing the inside seal area of the tube is heated by high frequency friction produced by an ultrasonic horn. The tube is then clamped against the anvil and cooled to form the tube seal.

Ultrasonic seal will not harm the material inside and sealing is more neat and stable. If you require high quality and stable sealing result, ultrasonic sealing type is highly suggested.

If you have different tube diameter, ultrasonic sealing machine only need to change the tube holders and no need to change the preheating parts, the cost and time needed is much less.

Meanwhile, since ultrasonic sealing is cold seal, you do not need an industrial chiller to work with. Saving both the floor space and electricity bill.

So welcome to contact HX Machine now, your one-stop packaging machine supplier and let us help you!

Post time: Aug-07-2020